How to Choose High-Quality Sand-Filled TPR Toys

In today’s market, sand-filled TPR toys are popular among consumers for their unique texture and diverse play options. However, with so many suppliers and products available, choosing high-quality sand-filled TPR toys becomes a critical issue.

1. Understanding the Key Properties of TPR Materials

TPR (thermoplastic rubber) is a material that combines the elasticity of rubber with the processing properties of plastic. When selecting sand-filled TPR toys, it’s important to first understand the key properties of TPR materials to ensure product quality and safety.

(1) Environmental Performance

The environmental performance of TPR materials is crucial. High-quality sand-filled TPR toys should comply with international environmental standards, such as RoHS and EN71-3. These standards require that TPR materials be free of hazardous substances such as heavy metals, polycyclic aromatic hydrocarbons (PAHs), and nonylphenol (NP). Furthermore, depending on the export market, other specific environmental requirements may also need to be met. (II) Physical Properties

Crack Resistance: For softer TPR toys, appropriate TPR material should be selected to avoid cracking after processing. Stress-induced cracking can be reduced by optimizing the molding process.

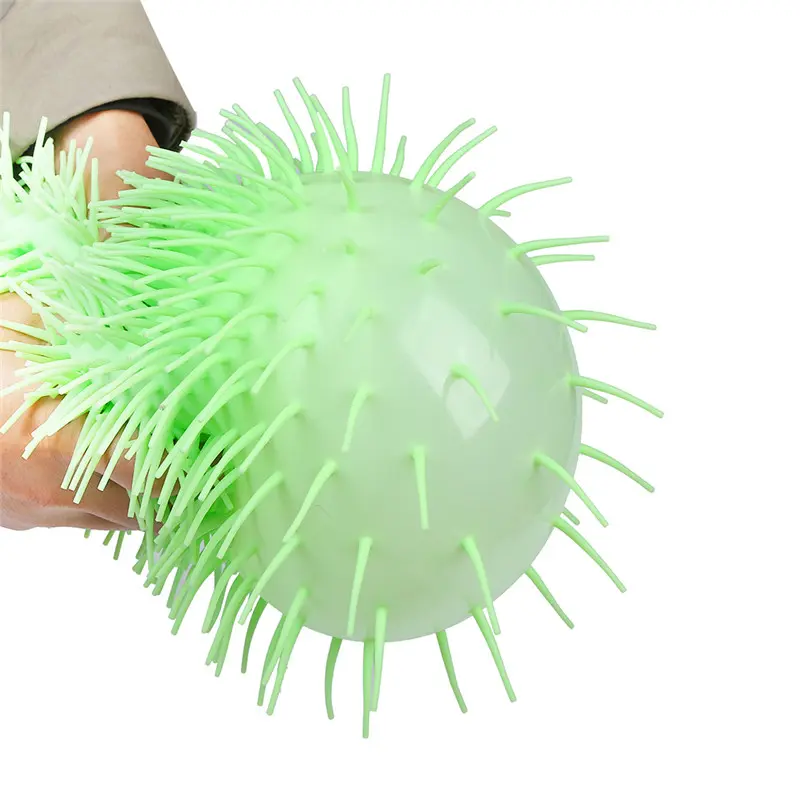

Elasticity and Flexibility: TPR material exhibits good flexibility and high resilience, allowing it to withstand certain bending and stretching without deforming. This is particularly important for sand-filled toys, which need to maintain their shape and structural integrity during play.

Abrasion Resistance: High-quality sand-filled TPR toys should exhibit excellent abrasion resistance, maintaining a smooth and intact surface even with frequent use. This not only helps extend the toy’s lifespan but also reduces the generation of small particles from wear and tear, which could be ingested by children.

(III) Processing Performance

TPR material has moderate flowability, making it easy to mold. Injection molding temperatures are typically between 170 and 190°C, which helps prevent shrinkage and burrs. Additionally, cooling during processing is important to minimize odor. For SBS-based TPR figurine materials, the processing temperature should be kept low to minimize aging and odor issues. (4) Color Matching Performance

Sand-filled TPR toys come in a wide variety of colors, so the TPR material requires good color pigment diffusion properties. This helps achieve vibrant and uniform colors. When selecting toys, pay attention to color uniformity and vividness to avoid color shifts or fading.

(5) Odor

Although TPR/TPE inevitably have an odor, this can be reduced to an acceptable level through optimization of the formulation and process. Different manufacturers use different formulations, resulting in varying odors. When choosing sand-filled TPR toys, choose products with a milder odor.

2. Pay Attention to the Toy Manufacturing Process

When selecting sand-filled TPR toys, it is equally important to understand the manufacturing process. High-quality manufacturing processes ensure the quality and safety of the toys.

(1) Molding Process

The molding processes for sand-filled TPR toys typically include injection molding and extrusion. Injection molding allows for precise control of the toy’s shape and size, ensuring product accuracy and consistency. Extrusion is suitable for producing toy parts with continuous shapes. When selecting toys, check the surface smoothness and dimensional accuracy to assess the quality of the production process.

(2) Filling Process

The filling process of sand-filled toys can also affect their quality and safety. High-quality sand-filled TPR toys should use environmentally friendly and non-toxic filling materials, ensuring that the filling is evenly distributed. The filling should not contain sharp particles or foreign matter to avoid harm to children. Furthermore, the filling should be tightly bonded to the TPR material to prevent leakage during play.

(3) Quality Testing

Strict quality testing during the production process is a key step in ensuring the quality of sand-filled TPR toys. Manufacturers should conduct rigorous inspections of raw materials to ensure they meet environmental and quality standards. During the production process, regular sampling tests should be conducted to check whether the toys meet requirements for size, shape, color, odor, and other aspects. The final product should undergo comprehensive quality testing, including physical and environmental performance testing, to ensure product safety and reliability.

3. Selecting a Reliable Supplier

Selecting high-quality sand-filled TPR toys requires a reliable supplier. When selecting a supplier, consider the following aspects:

(I) Supplier Qualifications and Reputation

Suppliers should possess relevant production qualifications and certifications, such as ISO 9001 Quality Management System Certification and ISO 14001 Environmental Management System Certification. These certifications demonstrate that the supplier adheres to strict quality and environmental standards during production. Furthermore, it is crucial to understand the supplier’s market reputation and customer reviews. Selecting a supplier with a strong reputation and extensive experience can reduce procurement risks and ensure product quality.

(II) Supplier Quality Control System

Suppliers should have a comprehensive quality control system, with strict quality testing and control measures in place at every stage, from raw material procurement to finished product shipment. Understanding the supplier’s quality control processes, such as raw material inspection, in-production quality monitoring, and finished product inspection, will help you assess the consistency of their product quality.

Post time: Aug-08-2025