I. Compliance First: A “Mandatory Course” for Global Toy Trade

Europe, as the world’s second-largest toy consumer market (over €38 billion in 2024), has a 42% share of cross-border e-commerce channels. However, over 35% of the substandard toys detained by EU customs each year are due to “lack of CE certification” or “excessive levels of hazardous substances.” For stress-relieving toy companies targeting global distributors, RoHS and EN71 certifications are not optional—they are core credentials for overcoming trade barriers and mitigating legal risks, and are the cornerstone of building trust with distributors.

II. Core Certification Analysis: RoHS and EN71′s “Safety Bottom Line”

1. RoHS Certification: The “Non-Toxic Passport” for Electronic and Electrical Toys

Scope of Application: Covers plastic toys with electrical functions (such as light-up decompression balls and electric squeeze toys). EU Directive 2011/65/EU explicitly includes toys under control, including cables and spare parts.

Controlled Substances and Limits:

Cadmium (Cd) ≤0.01% (100ppm), Lead, Mercury, Hexavalent Chromium, etc. ≤0.1% (1000ppm);

Phytaldehyde esters (DEHP, DBP, etc.) are a key focus. Although not currently mandatory testing, they are included in the priority assessment list, and some markets (such as the EU) have additional controls through REACH regulations.

Wholesalers’ Note: Electronic components (such as batteries and motors) and plastic shells of decompression toys must meet the requirements to avoid the entire batch of goods being detained due to a single component exceeding the limit. 2. EN71 Certification: The EU’s “Comprehensive Test” for Toy Safety

As the core testing standard for CE certification, EN71 covers all dimensions of safety requirements, including physical, chemical, and flammability. Key aspects directly related to decompression toys include:

EN71-1 (Physical and Mechanical Safety):

Small Parts Control: For toys for children under 3 years old, detachable parts must be ≥31.75mm to avoid swallowing risks (special attention should be paid to detachable decorations on decompression toys);

Tension Test: Plush/plastic accessories must withstand a 70N tensile force for 10 seconds without detaching, and the radius of the rounded corners must be ≥0.5mm.

EN71-3 (Heavy Metal Migration): Tests for the migration of 15 heavy metals, with lead ≤90ppm and cadmium ≤75ppm. The standard is stricter than the US CPSIA.

EN71-2 (Flammability): For plush decompression toys, the flame spread rate must be ≤100mm/min, with no molten dripping.

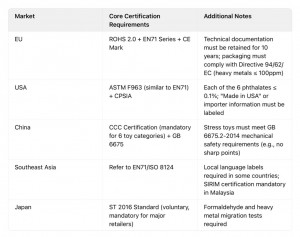

III. Global Market Compliance Differences: Essential “Regional Rules” for Wholesalers

IV. Compliance Risks and Countermeasures for Wholesalers

1. Typical Risk Cases

In 2024, a company in Yiwu exported infringing plastic toys. Due to non-compliance standards and trademark infringement, the goods were detained and penalized by customs, involving a value exceeding 8,000 yuan.

The Shanghai Market Supervision Bureau found that 27 batches of “pimple-squeezing stress-relieving toys” did not meet national standards, 26 batches contained unlabeled sharp needles, and 12 batches had excessively thin plastic bags (potentially causing suffocation). 2. Practical Guide to Avoiding Pitfalls

* **Certification Verification:** Require suppliers to provide test reports issued by EU notified bodies (SGS, TÜV) to verify the clarity of the CE marking (height ≥ 5mm) and batch consistency.

* **Supply Chain Management:** Avoid material substitution during mass production (e.g., submitting lead-free material for testing but actually using lead-containing PVC). It is recommended to introduce third-party inspection and sampling of materials.

* **Labeling Standards:** Include applicable age groups (e.g., “3+”), warning statements (multi-language versions), and the manufacturer’s EU address to ensure traceability.

* **Regulatory Updates:** EN71-3 is revised annually, and RoHS may add new controlled substances. Regularly monitor ECHA (European Chemicals Agency) announcements. V. The Commercial Value of Compliance: More Than Just Avoiding Penalties

Expanding into High-Value Markets: RoHS/EN71 certification allows direct access to high-end markets such as the EU and Japan. CE certification and test reports are required for listing on Amazon Europe.

Reducing Cooperation Risks: Compliant products reduce returns and claims for distributors. Data from a cross-border toy company shows that compliance certification can reduce return rates by 40%.

Building Brand Barriers: In the homogeneous competition of stress-relief toys, “dual certification guarantees” have become a core decision-making basis for distributors when choosing suppliers, increasing repurchase rates.

VI. Special Compliance Reminders for Stress-Relief Toys

Stress-relief toys with electrical functions (such as light-up and sound-emitting models) must additionally comply with EN 62115 electrical safety standards (protection against electric shock and overheating).

Soft plastic materials must pass thickness testing (average ≥0.038mm). Avoid using excessively thin packaging plastic bags.

Avoiding Infringing Designs: Cartoon characters and trademarks on stress-relief toys must be authorized. Avoid infringing marks such as “Ultraman” and “Paw Patrol.”

Post time: Nov-07-2025