Chemical safety requirements and test items for TPR toys

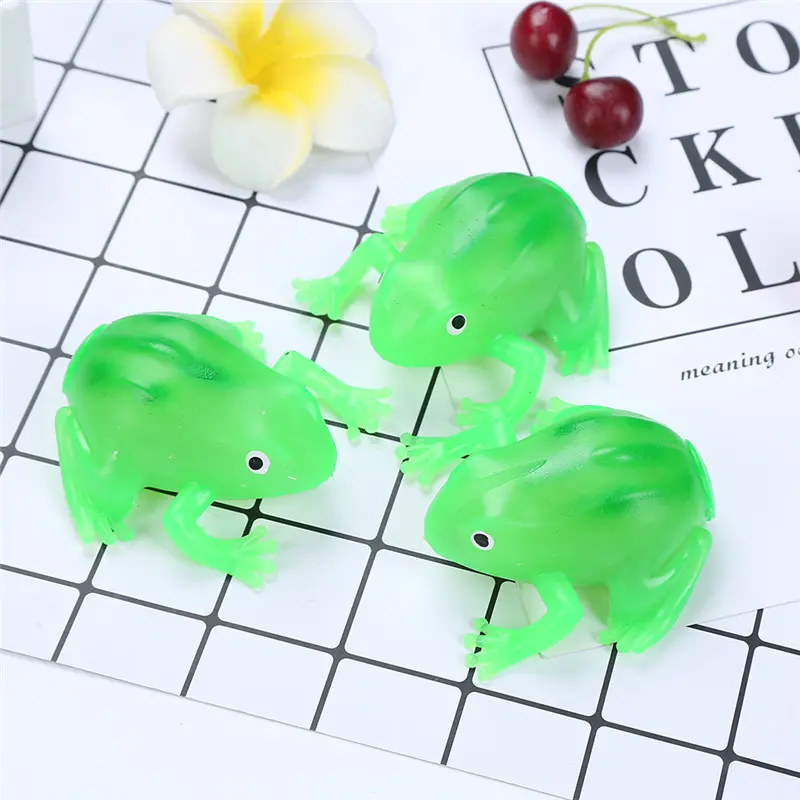

In today’s toy market, TPR toys are popular because of their unique material properties. TPR (thermoplastic rubber) is a material that combines the advantages of plastic and rubber. It has good elasticity, flexibility, low temperature resistance and high temperature resistance, etc. It can be used to make toys of various shapes and sizes, such as toy dolls, toy wheels, teethers, etc.

However, since TPR toys are mainly aimed at sensitive groups such as children, their chemical safety is crucial. For international wholesale buyers engaged in the export business of TPR toys, understanding and ensuring that the products meet the relevant chemical safety requirements and pass the corresponding test items is the key to entering the market.

Chemical safety requirements and test items in the European Union

REACH Regulation

REACH Regulation is a regulation of the European Union for the preventive management of all chemicals entering its market. Certain chemicals in TPR toys may be included in the scope of control of REACH Regulation. Enterprises need to register, evaluate, license and restrict chemicals in toys to ensure the safety of products. For example, some harmful chemicals such as certain plasticizers, flame retardants, etc. may be restricted or require authorization to use.

EN71 Standard

EN71-3: Eight Heavy Metal Dissolution Test: Mainly tests the dissolution of eight heavy metals such as antimony, arsenic, barium, cadmium, chromium, lead, mercury, and tin in TPR toys. If these heavy metals are absorbed by children through oral or skin contact, they may cause harm to the body, such as affecting the nervous system, hematopoietic system, etc. The test method is usually to place the toy sample in a solution simulating human gastric juice or sweat, and then analyze the dissolved heavy metal content by atomic absorption spectroscopy.

EN71-9: Organic compound test: Restricts the migration of specific organic compounds in toys, including a variety of harmful chemicals such as certain aromatic amines, benzene, formaldehyde, etc. These substances may have risks such as carcinogenicity, teratogenicity, mutagenicity, etc., or may cause irritation and damage to children’s respiratory system, skin, etc. During the test, the corresponding detection method should be adopted according to the specific organic compound, such as gas chromatography-mass spectrometry, etc.

Chemical safety requirements and testing items in the United States

CPSIA (Consumer Product Safety Improvement Act)

Lead content limit: CPSIA strictly limits the lead content in toys. Because lead can cause serious damage to children’s nervous system, etc., the regulations stipulate that the lead content in the surface coating of toys shall not exceed 90ppm, and the total lead content of any accessible parts in toy products shall not exceed 100ppm. The test method usually uses inductively coupled plasma mass spectrometry to analyze the samples.

Phthalates content limit: In order to prevent the potential harm of phthalates to children’s reproductive system, etc., CPSIA also limits the phthalates content in toys. For toy parts that can be put into children’s mouths, the content of DEHP, BBP, and DBP shall not exceed 0.1%; for all toy products, the content of DnOP, DIDP, and DINP shall also not exceed 0.1%. Professional testing equipment and methods, such as gas chromatography-mass spectrometry, are required for quantitative analysis of phthalates during testing.

ASTM F963 standard

Physical and mechanical properties test: Although it is not a chemical safety test item, it is closely related to chemical safety. For example, the small parts test can prevent the production of small parts due to the breakage of toy parts, avoiding the risk of harmful chemicals being released into the body after children accidentally ingest it. The sharp edge and point test can prevent children from being scratched by toys, thereby reducing the possibility of wounds being exposed to harmful chemicals.

Combustion performance test: Ensure that TPR toys are not easy to ignite and that the burning speed meets the specified requirements when on fire to prevent fire from causing harm to children. The test method is to place the toy sample in a specific flame source and observe its burning speed and self-extinguishing properties.

Chemical safety requirements and test items in other regions

Canada

Canada’s toy safety regulations are similar to those of the United States. They also strictly restrict heavy metals such as lead and cadmium and harmful chemicals such as phthalates in toys. Its test methods and limit requirements are similar to those of the US CPSIA and ASTM F963 standards.

Australia and New Zealand

TPR toys are tested according to AS/NZS ISO 8124, including tests on mechanical and physical properties, combustion performance, and migration of specific elements. The migration test of specific elements covers a variety of heavy metal elements. The test principle and method are similar to the EN71-3 standard, which aims to limit the dissolution of these harmful elements in toys and protect children’s health.

Chemical safety characteristics and tests of TPR toys themselves

Non-toxic property test

TPR materials themselves should have non-toxic properties, and the compounding agents used in their formulas should be mild, non-corrosive and non-irritating raw materials. Testing is required by third-party testing agencies such as SGS to ensure that TPR toys meet relevant environmental standards, such as halogen-free, phthalate plasticizers, polycyclic aromatic hydrocarbons PAHs, nonylphenol NP, heavy metals and radioactive elements, bisphenol A, etc.

Oil resistance test

For some TPR toys that may come into contact with oil substances, such as toy wheels, oil resistance tests are required. This test mainly measures the changes in multiple performance indicators of TPR materials in different standard reference oils, such as volume, hardness, tensile strength, etc., to ensure the performance stability and safety of toys under normal use conditions.

Conclusion

It is crucial for companies engaged in TPR toy export business to ensure that TPR toys meet the chemical safety requirements of the international market and pass the corresponding test items. This is not only a prerequisite for meeting the regulatory requirements of various countries and entering the market smoothly, but also the key to ensuring the health and safety of children and establishing a good corporate image. Enterprises should fully understand and strictly follow the relevant standards and regulations of the target market, strengthen raw material procurement control, production process management, and product quality testing, and produce high-quality TPR toys that meet chemical safety requirements, so as to win the trust and recognition of customers in the international market and achieve sustainable development.

Post time: May-21-2025