Are environmentally friendly materials used in the production of Puffer Balls?

In today’s society, the increase in environmental awareness has prompted more and more companies and manufacturers to use environmentally friendly materials in product production. As a popular toy, whether environmentally friendly materials are used in the production process of Puffer Balls has also become the focus of attention of consumers and manufacturers. This article will explore whether environmentally friendly materials are used in the production of Puffer Balls, as well as the application and advantages of environmentally friendly materials in toy manufacturing.

1. Definition and use of Puffer Balls

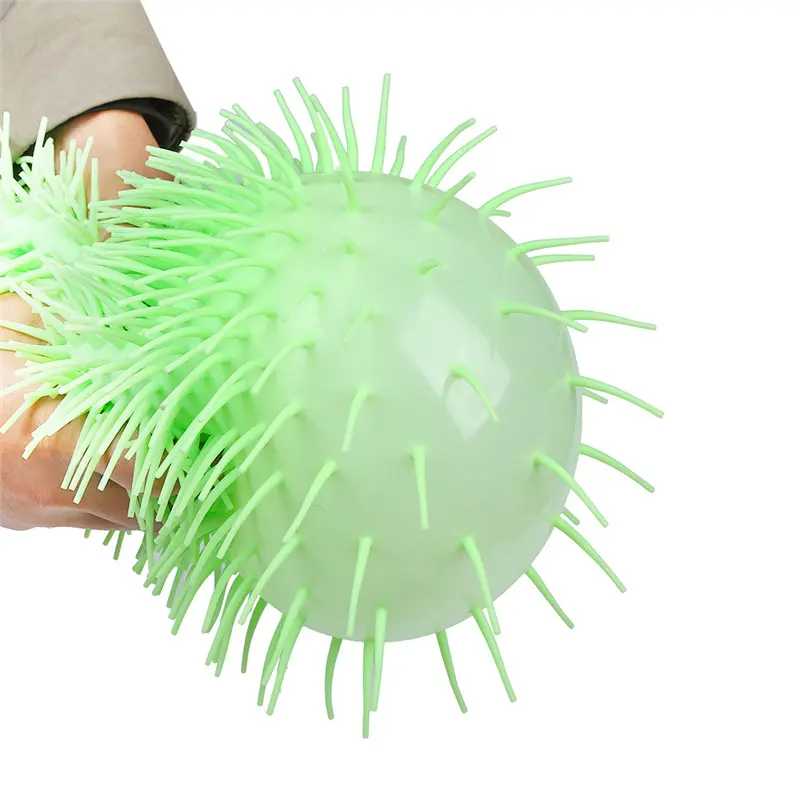

Puffer Balls are a common squeeze toy that is widely popular because of its lightness, softness and elasticity. They are often used to relieve stress, provide sensory stimulation, or as toys for children. Puffer Balls have a variety of designs, ranging from simple circles to various animals or cartoon characters, which makes them highly attractive to consumers of different ages.

2. Application of environmentally friendly materials in the production of Puffer Balls

(I) Selection criteria for environmentally friendly materials

Environmentally friendly materials refer to materials that have little impact on the environment during production, use and disposal. When choosing environmentally friendly materials, the following criteria are usually considered:

Low pollution: less pollutants are emitted during the production process, and the impact on the environment is small.

Renewable: derived from renewable resources such as bamboo, wood, etc., rather than non-renewable resources such as oil and coal.

Recyclable: can be recycled and reused after use, reducing the generation of garbage.

Biodegradable: can be decomposed quickly in the natural environment and will not cause long-term pollution.

Energy saving: low energy consumption during production and use, which helps to save energy.

(II) Environmentally friendly materials used in Puffer Balls

In the production of Puffer Balls, some manufacturers have indeed begun to use environmentally friendly materials to reduce the impact on the environment. The following are some common environmentally friendly materials and their applications:

Bio-based materials

Polylactic acid (PLA): PLA is a bioplastic made from plant starch with good biodegradability. It can be decomposed in a relatively short time in the natural environment, reducing pollution to the environment.

Corn fiber and sugarcane fiber: These materials are derived from renewable resources and have good environmental performance. For example, Adidas uses environmentally friendly raw materials such as corn fiber and sugarcane fiber when producing footballs.

Recyclable materials

Recycled plastics: Through recycling and reprocessing, waste plastics are made into new products. This not only reduces the generation of plastic waste, but also saves resources.

Natural materials

Natural rubber: Natural rubber is a renewable resource with good elasticity and wear resistance, suitable for making Puffer Balls.

Sodium alginate: Sodium alginate is a natural biodegradable polymer with good mechanical properties and environmental protection characteristics. Studies have shown that sodium alginate can be used to produce high-performance foam materials.

(III) Advantages of environmentally friendly materials in the production of Puffer Balls

Reduce environmental pollution: The use of environmentally friendly materials can significantly reduce the pollution to the environment during the production process, and at the same time, the product can be degraded faster after it is discarded, reducing garbage accumulation.

Improve product safety: Environmentally friendly materials are usually less toxic and safer for consumers, especially children.

In line with market trends: As consumers’ environmental awareness increases, products using environmentally friendly materials are more likely to gain market recognition.

3. Examples of environmentally friendly materials used in the production of Puffer Balls

(I) Xiaotaoqi’s environmental practices

Xiaotaoqi is a well-known toy manufacturer that insists on using environmentally friendly materials in the production of Puffer Balls. The company said that its products not only focus on safety, but also strive to reduce environmental impact through environmentally friendly materials and production practices. Xiaotaoqi’s Puffer Balls use environmentally friendly materials such as PVA (polyvinyl alcohol), which has good biodegradability and can be decomposed in the natural environment.

(II) Ameson’s biodegradable bubble bags

Ameson is a manufacturer focusing on environmentally friendly packaging materials. The biodegradable bubble bags it produces use PBAT (polybutylene adipate/terephthalate) environmentally friendly materials. This material has good cushioning properties and air tightness, and can be completely degraded into water and carbon dioxide within one year under composting conditions. Although PBAT is mainly used for packaging materials, its environmental protection concept is also applicable to the production of Puffer Balls.

4. Challenges of using environmentally friendly materials in the production of Puffer Balls

Although environmentally friendly materials have many advantages in the production of Puffer Balls, they still face some challenges in practical applications:

Cost issues: The production cost of environmentally friendly materials is usually higher than that of traditional materials, which may lead to an increase in product prices.

Performance differences: The performance of some environmentally friendly materials may not be as good as that of traditional materials, such as in terms of strength and durability.

Market acceptance: Consumers have different perceptions and acceptance of environmentally friendly materials. Some consumers may pay more attention to the price and performance of the product rather than its environmental characteristics.

Post time: Feb-12-2025